15 Essential Inventory Management Techniques

Using inventory management software is one of the best types of inventory management techniques for automating processes and tracking stock. By calculating the optimal order quantity, you can avoid stockouts that lead to lost sales while also minimising the holding costs of excess inventory. This technique allows you to maintain a lean and efficient inventory system, improve customer satisfaction, and reduce costs. By ordering the right inventory quantity at the right time, you can optimise your operations and maximise profitability. It consolidates related items into cohesive units, supporting flexible product offerings.

Steps to Conduct ABC Analysis

Try strategically placing these zones to ensure smooth movement of products, staff, and equipment, minimize congestion, and improve workflow. Proper stock levels also ease vendor relationships by reducing the need for last-minute orders, which can cause financial strain and disrupt partnerships. In most cases, the first items you add to your inventory will be the cheapest since prices typically rise over time.

Key Inventory Management Techniques

- This approach helps ensure that products are always available for customers, even if there are supply chain disruptions or sudden spikes in demand.

- To forecast effectively, companies must consider several factors, including current stock levels, past sales trends, and expected changes in demand.

- Minimum order quantity (MOQ) refers to the lowest amount of stock that a supplier will sell to you.

- Incorporating the 80/20 rule helps businesses boost efficiency and make smarter decisions.

- For instance, a firm that deals in finished goods does not hold any physical inventory of its own, or sells wholesale products, and will not require any manufacturing or production.

- Demand forecasting, or demand planning, involves predicting future inventory needs based on historical data and upcoming events.

Advanced systems not only automate the tracking and recording of inventory but also provide real-time analytics and forecasting. This allows retailers to accurately predict demand trends, reduce overstock, and minimize understock situations. By investing in robust inventory management software, retail stores can significantly reduce the time spent on manual stock checks and data entries. There are various inventory management techniques that businesses can use to optimize their inventory levels and processes. Today, all Law Firm Accounts Receivable Management these details can easily be stored in inventory management software that keeps track of all your stock, purchase orders, bulk shipments, supplier trucks, etc.

- Effective inventory management leads to a responsive and resilient supply chain management.

- The system deducts the quantity sold from your inventory records whenever a sale is made.

- Cross-docking is a supply chain tactic used to reduce inventory costs and speed up delivery times.

- Historical sales data reveals trends and seasonal fluctuations, allowing businesses to anticipate customer needs.

- Lost, obsolete or overstocked inventory drives up costs and destroys margins.

- The inventory management strategy known as First In, First Out (FIFO) prioritizes the sale of the oldest stock first.

Case Studies/Examples of Companies Using Each Technique

The JIT method is suitable for businesses that deal with perishable or fast-moving items. Radio-frequency identification (RFID) technology has revolutionized inventory management. By attaching RFID tags to items, retailers can automatically track the movement and quantity of stock across different store locations. This technology provides accurate real-time inventory data, significantly reduces discrepancies, and enhances the security of stock items. Investing in RFID systems will streamline operations and improve inventory accuracy in retail store display supplies. Navigating the complexities of inventory management in retail stores can be a daunting task, especially with a diverse array of products and evolving consumer demands.

Establish regular inventory cycle counts.

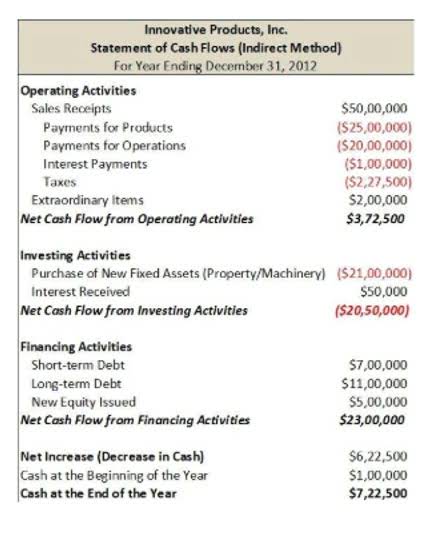

Further, inventory management provides forecasts and insights in real-time to better understand the number of products sold, inventory unsold, and projected sales in a particular period. This helps companies plan better to produce and manage inventory in a better way. An inventory audit compares your payroll actual inventory levels to your financial records, as a way to guarantee accurate inventory accounting. Sometimes, inventory audits are as simple as performing a physical inventory count of your existing stock, while other times they might involve a third-party auditor.

In this method, suppliers transfer their goods directly to outbound vehicles for shipment. Immediately delivering items to retailers can help cut holding and warehouse costs. Learn about the different types of inventory management techniques and online store inventory management discover how they can transform your inventory handling practices. For the most accurate data, consider using perpetual inventory management software, as it is the best way to ensure the information you need is always at your fingertips.

EOQ Model

- It ensures you have the right products in the right quantities at the right time.

- This helps businesses maintain profitable margins while meeting supplier requirements.

- Inventory management is crucial to prevent loss of items, quickly fulfill customer orders and know when you need to buy more of a given product.

- This helps companies plan better to produce and manage inventory in a better way.

- With this equation, you can stop being a victim to market spikes and slumps and consistently order the right amount of stock every month.

To successfully implement cross-docking, businesses need robust coordination with suppliers and carriers, real-time visibility of inventory, and efficient sorting and loading processes. Effective use of technology and strategic location planning of cross-docking facilities are also crucial for optimizing operations. LIFO is particularly beneficial for businesses in industries with significant price volatility, such as oil and gas, where recent purchase costs are higher. Yet, it is less suited for businesses needing accurate inventory tracking or operating in markets where prices are stable or declining. Given its complexity and varying global acceptance, companies must evaluate their specific needs and regulatory environment before adopting LIFO.

- Veröffentlicht in Bookstime